Rega Pabrik Gulungan Baja Tahan Karat 304 304L Cold Rolled

| barang | nilai |

| Aplikasi | Dekorasi, Pawon, lsp. |

| Kekandelan | 0.3-50mm |

| Standar | GB |

| Jembar | 3mm-2000mm utawa miturut kabutuhan |

| Sertifikat | API, ce, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 |

| Kelas | Seri 300 |

| Toleransi | ±1% |

| Layanan Pangolahan | Pengelasan, Peninjuan, Pemotongan, Pembengkokan, Decoiling |

| Kelas Baja | 301L, S30815, 301, 304N, 310S, S32305, 410, 204C3, 316Ti, 316L, 441, 316, 420J1, L4, 321, 410S, 436L, 410L, 443, Ngisor, L1, S32304, 314, 347, 430, 309S, 304, 439, 425M, 409L, 420J2, 204C2, 436, 445, 304L, 405, 370, S32101, 904L, 444, 301LN, 305, 429, 304J1, 317L |

| Rampungan Permukaan | TSHS |

| Wektu Pangiriman | 8-14 dina |

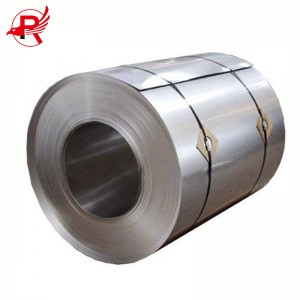

| Jeneng produk | Kumparan Baja Tahan Karat |

| Teknik | Digulung Adhem Digulung Panas |

| Tipe | Strip Kumparan Pelat Lembar |

| Standar | AISI ASTM JIS DIN GB |

| Permukaan | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Dawane | Panjaluk Pelanggan |

| MOQ (Kebutuhan Keuangan) | 1 Ton |

| Aplikasi | Konstruksi |

| Pengepakan | Kemasan Standar sing Layak Dilaut |

| Pambayaran | Deposit 30% + Uang Muka 70% |

Baja tahan karat 304 304L sing nduweni kemampuan las sing apik banget, tahan korosi sing apik, lan kekuatan sing dhuwur. Iki minangka bahan sing ideal kanggo macem-macem aplikasi kalebu peralatan pangolahan panganan lan peralatan pangolahan kimia.

Ing ngisor iki dhaptar sawetara aplikasi sing luwih umum kanggo koil baja tahan karat 304 304L:

1. Piranti Pangolahan Pangan & Piranti Pangolahan Kimia

2. Industri Lenga & Gas

3. Aplikasi Kelautan

Cathetan:

1. Sampling gratis, jaminan kualitas purna jual 100%, Ndhukung cara pembayaran apa wae;

2. Kabeh spesifikasi pipa baja karbon bunder liyane kasedhiya miturut kabutuhan sampeyan (OEM & ODM)! Rega pabrik sampeyan bakal entuk saka ROYAL GROUP.

Komposisi Kimia Kumparan Baja Tahan Karat

| Komposisi Kimia % | ||||||||

| Kelas | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0,03 | 3.5 -5.5 | 16.0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0,03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0,03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0,03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0,03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0,03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0,03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0,03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0,03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0,03 | 12.0 - 15.0 | 16.0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0,03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0,03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0,03 | 0.19 -0.22 | 0. 24 -0. 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0,03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0,03 | ≤0.60 | 16.0 -18.0 | |

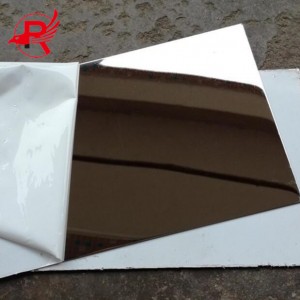

Liwat macem-macem cara pangolahan rolling adhem lan pangolahan ulang permukaan sawise rolling, lapisan permukaan gulungan baja tahan karat 304 304L bisa duwe macem-macem jinis.

Pangolahan permukaan gulungan baja tahan karat duwe NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled padhang 2H, polesan padhang lan polesan permukaan liyane, lan liya-liyane.

1. Rampungan No. 1: Rampungan iki digawe saka baja tahan karat canai panas kanthi kekasaran lan kusam tartamtu. Iki minangka rampungan sing paling umum digunakake lan nduweni tampilan sing luwih kasar.

2. Rampungan 2B: Iki minangka rampungan reflektif alus sing ditindakake dening baja tahan karat sing digulung adhem. Rampungan 2B minangka rampungan permukaan baja tahan karat sing paling akeh digunakake.

3. Rampungan BA: Rampungan iki nduweni tampilan kaya pangilon sing mantul banget. Iki ditindakake kanthi polesan baja tahan karat nganggo abrasif sing saya alus nganti entuk permukaan sing polesan banget.

4. Rampungan No.4: Rampungan iki nduweni tampilan sing disikat utawa kaya satin, sing digayuh kanthi nggawe pola disikat searah ing permukaan baja tahan karat.

5. Polesan No.8: Iki minangka polesan sing paling reflektif lan kaya pangilon, sing digayuh kanthi polesan baja tahan karat nganggo abrasif sing alus banget nganti permukaane reflektif banget.

Proses produksi kumparan baja tahan karat biasane nglibatake sawetara tahapan, kalebu:

1. Peleburan: Proses produksi diwiwiti kanthi peleburan bahan mentah kayata wesi, nikel, kromium, lan liya-liyane ing tungku.

2. Mbentuk: Tuang baja cair menyang cetakan persegi panjang utawa batangan baja, banjur gulung dadi pelat utawa gulungan sing rata.

3. Annealing: Lembaran utawa koil baja tahan karat banjur dianil, utawa dipanasake lan didinginkan ing lingkungan sing dikontrol, kanggo ngurangi stres lan nambah kekuatan lan daktilitas logam.

4. Penggulungan adhem: Baja tahan karat banjur digulung adhem, utawa dilewati serangkaian gulungan, kanggo ngurangi kekandelane lan nambah permukaane.

5. Anil lan pengawetan: baja tahan karat banjur dianil lan diasinake, utawa diolah nganggo larutan asam kanggo mbusak rereged permukaan lan nambah ketahanan korosi.

6. Rampungan: Gulungan baja tahan karat banjur dipotong miturut ukuran lan diwenehi macem-macem perawatan permukaan kayata polesan, nggiling utawa lapisan.

7. Kontrol Kualitas: Sajrone proses produksi, gulungan baja tahan karat dipriksa lan diuji kanggo mesthekake yen wis memenuhi syarat kekuatan, tahan korosi, lan lapisan akhir.

kemasan laut standar saka kumparan baja tahan karat 304 304L

Kemasan laut ekspor standar:

Gulungan Kertas Tahan Air + Film PVC + Tali Pengikat + Palet Kayu utawa Wadah Kayu;

Kemasan khusus miturut panyuwunan sampeyan (Logo utawa isi liyane ditampa kanggo dicithak ing kemasan);

Kemasan khusus liyane bakal dirancang miturut panyuwunan pelanggan;

Transportasi:Pangiriman Ekspres (Pangiriman Sampel), Udara, Rel, Darat, Laut (FCL utawa LCL utawa Curah)

P: Apa pabrikan ua?

A: Inggih, kita punika produsen. Kita gadhah pabrik piyambak ingkang dumunung ing Kutha Tianjin, Tiongkok. Saliyané iku, kita ugi makarya bareng kaliyan kathah perusahaan milik negara, kados ta BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, lan sanès-sanèsipun.

P: Apa aku isa pesen uji coba mung pirang-pirang ton?

A: Mesthi wae. Kita bisa ngirim kargo kanggo sampeyan nganggo layanan LCL. (Muatan kontainer luwih sithik)

P: Yen conto gratis?

A: Sampel gratis, nanging panuku mbayar kanggo pengiriman.

Q: Apa sampeyan pemasok emas lan nindakake jaminan perdagangan?

A: Kita pitung taun pemasok emas lan nampa jaminan perdagangan.